The best adhesive to use for bonding neoprene rubber

Choosing the right adhesive for bonding synthetic rubbers, such as neoprene, is a challenge. Rubber is notoriously difficult to bond, due to its composition and chemical resistance, and what works for one type may not work for another. Polymer rubbers such as neoprene create even more problems. Neoprene is used in many different applications, such as automotive insulation, sports equipment, wetsuits and gaskets, with varying thermal and physical requirements. The adhesive used will also need to meet these requirements, so it is important to understand the differences. With the right glue, a little preparation and the correct amount of pressure, bonding neoprene is possible.

What is neoprene rubber?

Neoprene rubber is a type of synthetic rubber that is produced by polymerizing chloroprene. It is a highly versatile, durable and flexible material that has many practical applications. Neoprene rubber, chemically known as polychloroprene, is known for its excellent resistance to heat, weathering, oils, and chemicals. These properties make it ideal for use in harsh environments.

Neoprene is also valued for its excellent mechanical properties, such as its high tensile strength, elasticity, and abrasion resistance. Neoprene rubber is commonly used in producing gaskets, hoses, wetsuits, orthopaedic braces, sports equipment and other products where a high degree of durability and resistance to the elements is required.

How is neoprene rubber sold?

It is possible to purchase neoprene rubber in many differing forms, depending on what is most useful for your application.

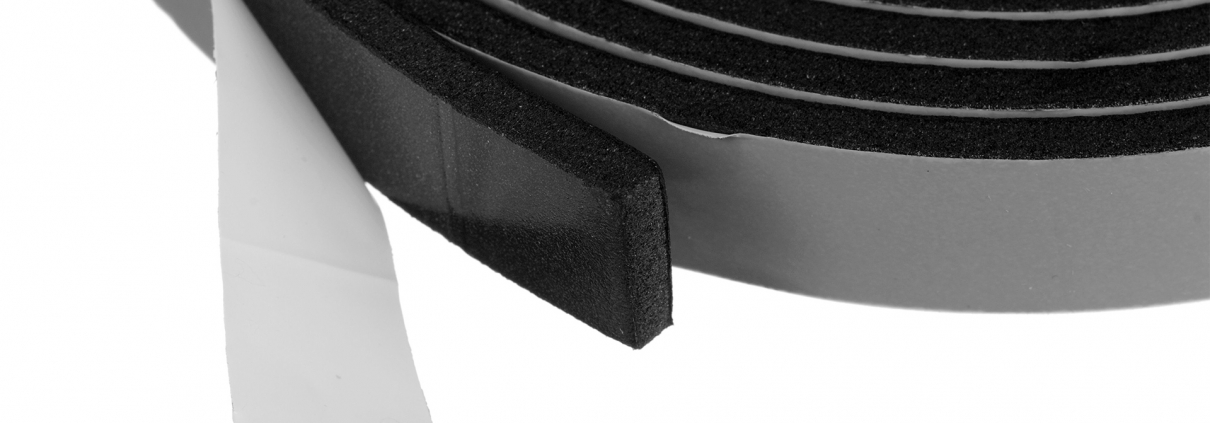

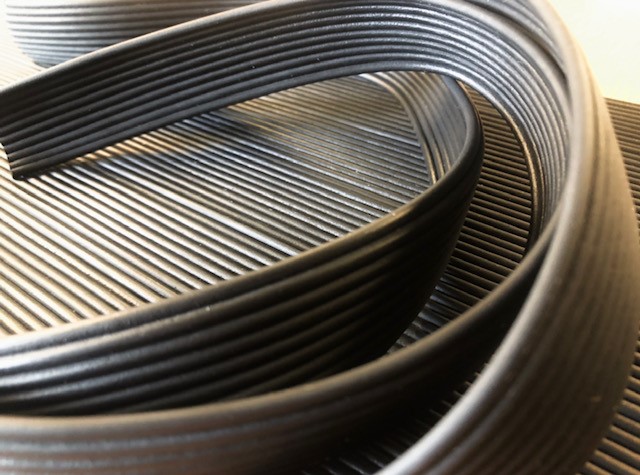

A Neoprene rubber sheet is sold in varying thicknesses, widths and lengths, useful for when you need to cover a wide surface area. Sheets are often sold as neoprene rubber rolls for easy storage and transportation. Neoprene rubber strips come in thin rolls of varying widths and thicknesses, coated with removable release tape. This allows easy storage and application. Neoprene strips are perfect for making seals or gaskets, especially in marine or outdoor conditions.

What is the best adhesive for neoprene rubber bonding?

Choosing the right adhesive for your application will ensure a smooth and reliable manufacturing process. There are different options available when glueing neoprene rubber. Here we take a look at the benefits and drawbacks of each.

Cyanoacrylate Adhesive (or Super Glue)

For most types of rubber, a cyanoacrylate instant adhesive is a reliable option to use. This is commonly known as ‘super glue’ and has a very fast setting speed, so you will know straight away if the bond will hold. A small amount of cyanoacrylate adhesive should form a strong bond between neoprene and other materials effectively in between 5-60 seconds, making it ideal for quick assembly. If the joint falls apart after curing, the adhesive may not be suitable. Specialised super-glue adhesives made for use with neoprene are available.

However, this fast-drying glue cannot be used on large areas, as any spreader or roller will be bonded to the material. The speed of drying also means if pieces are misaligned the join cannot be reset, possibly resulting in wastage.

Sticking or Bonding?

While using the above adhesives can effectively join neoprene and other materials together, there are still difficulties and disadvantages. Synthetic rubbers such as neoprene and silicone rubber are polymer-based and highly elastic, making them difficult to bond. Because of their weak intermolecular forces, neoprene can be bonded on a molecular level by using a polymer bonding agent, heat and high levels of pressure.

A molecular or covalent bond is more durable than a glue join, as the two pieces of material have essentially become one. A molecular bond then takes on the properties of the neoprene, becoming flexible, chemical- and oil-resistant and flame-retardant.

This mechanical bonding works to adhere two neoprene sheets together or to join neoprene with other polymer-based rubbers such as silicon. The method can even be used to make joins between neoprene and cotton, stainless steel, aluminium and other metals.

How to Bond Neoprene Rubber with Adhesive

Using cyanoacrylate adhesive or super glue is a good way to join the edges of neoprene sheets, or add a thin neoprene rubber strip to another substrate. It also works best with closed-cell neoprene rubber sheets where the edges can overlap. Follow this method to ensure your neoprene adheres well.

Prepare the surface

Begin by wiping the neoprene with isopropyl to remove any oil, debris or dust. Wipe the material dry using a clean towel, or wait for it to dry naturally. Ensure there is no residue.

You can also use steel wool or sandpaper to rough the surface of the neoprene where the bond will be. This increases the surface area, giving the adhesive more to grip onto.

Apply the Adhesive

Apply a small amount of cyanoacrylate adhesive to the edge of the neoprene, taking care not to get any on your skin. Glueing your hands to the materials can be painful.

Join the materials

Place the neoprene with the adhesive onto the substrate in exactly the right position, and apply pressure. Hold it in position for 5-60 seconds to ensure a tight bond.

When bonding neoprene, it is important to use the right type of adhesive for both neoprene and your substrate. The main recommendation is to use cyanoacrylate adhesive to bond neoprene, and while there are disadvantages to this method, it is the most readily available and easy to do. It is important to properly clean surfaces first, or you will simply be glueing neoprene to dust and dirt, rather than the intended surface. At Kirkfield Rubber and Adhesive products, our Neoprene Rubber Sheets are available as sheets, continuous neoprene rolls, prefabricated gaskets and neoprene strips, varying from 1.5mm-65mm thick.

Frequently Asked Questions

In this FAQ section, we will answer some of the most commonly asked questions about neoprene and the adhesives that work with neoprene, including properties, industrial uses, and best practices.

Is neoprene vulcanised rubber?

Vulcanised rubber is any rubber that has been hardened using sulphur or other curatives. This makes the rubber more rigid and durable. Neoprene rubber is a type of synthetic rubber that is produced by polymerizing chloroprene. It is sometimes vulcanised to produce different traits without changing the basic structure, and this is one way in which neoprene is a versatile material.

Is neoprene waterproof or resistant to water?

Neoprene is generally classed as waterproof, but it comes in two kinds: open-cell and closed-cell. Open-cell neoprene allows gas and fluids to pass through in varying amounts, so is not waterproof. Closed-cell neoprene, however, is waterproof. It is also higher density, more durable, more elastic and retains heat more easily.

How do I care for neoprene products to maintain their quality and longevity?

Products made from neoprene, from gaskets to wetsuits, are already known for their durability. However, to reduce costs and ensure they last a long time before they require replacement, you can take a few precautions and look after neoprene products well.

- Avoid prolonged heating. While neoprene is heat resistant, overexposure can cause brittleness.

- Avoid aerosols and solvents – these can stain and weaken the material.

- Always dry neoprene garments fully before storing them. This will avoid mould or mildew damaging the material.

- Clean with products designed for neoprene

- Rinse any salt water, oil or solvents from the neoprene with cold water after use.

- Avoid compressing folds in the neoprene, as this can cause weak points that eventually become holes.

Is neoprene a sustainable or eco-friendly material?

Neoprene or polychloroprene is a polymer or plastic material, derived from petrochemicals such as crude oil. These materials are considered ‘fossil materials’ because they are manufactured from the remains of ancient plant matter that has been stored below the earth. Because these are not renewable products, neoprene cannot be considered sustainable.

The processes of polymerisation and vulcanisation that produce neoprene contribute to carbon dioxide released into the atmosphere as well as air pollution near the factories, and the product does not biodegrade when it is no longer usable. This means that neoprene should not be considered a sustainable or eco-friendly material.

Can neoprene cause skin irritation or allergies in some people?

Some people can present allergic reactions or skin rashes when wearing products made from neoprene, such as wetsuits. This can include itching, swelling and redness known as neoprene splinting or neoprene rash.