How to Choose the Right Gasket Material for Your Project

How To Choose The Right Gasket Material

It’s important to align gasket material selection to the application environment to avoid the risk of failure. There is a huge variety of materials for gasket manufacture, and taking the time to research materials at the outset results in a long-lasting and reliable gasket. The main categories of gasket materials are metal, non-metal or soft and composite gaskets. As Kirkfield supplies various rubber gaskets, the main focus of this article is soft gasket materials and the differences between them.

Gasket Applications

Gaskets are used to cover the intersecting faces of two surfaces or parts. It could be a connection between two pipes, the gap between a window and a window frame, or the adjacent faces of two components. Gaskets are commonly used to create seals, either preventing leakage from or into a system or to prevent draughts. They are also used to reduce or prevent vibration, noise or friction, absorb shocks and insulate electrical components.

The Best Material for Gaskets Depends on Application

Selecting gasket materials requires a good knowledge of where the gaskets will be used and the conditions they will be under. The common factors to consider include:

- Temperature: the material will need to withstand both the minimum and maximum operating temperatures. This applies to both environmental temperatures surrounding the gasket and, if sealing pipes, the temperatures of fluids moving through the system.

- Chemical exposure: if the gasket is to be fitted in a chemical system or fuel line, choose non-reactive, chemical-resistant gasket material.

- Force: if the two surfaces will be tightened together, choose a material that will withstand the force required. Harder materials require higher compression forces and stress to create a seal, while easily compressed materials can create a seal under relatively low tension.

- Surface irregularities: Where the surfaces are not completely even, a material that is easily deformed, such as sponge rubber, will fill any gaps to provide full coverage.

- Ambient Contaminants: environmental debris such as dirt, dust and soot should be kept out of mechanical systems using gaskets at possible entry points such as control doors and joins.

- Internal Pressure: in air compressors and other pressurised systems, gaskets should be made from materials firm enough to withstand high pressures to avoid forced leaks.

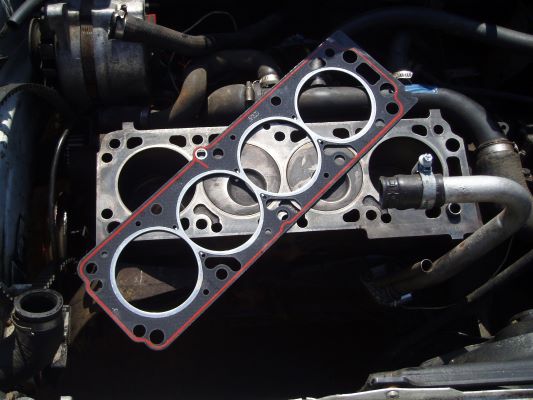

Metal Gaskets

Metallic gaskets or ring gaskets wedge between the connecting surfaces and can be secured with high-tension bolting to create an initial line contact or a strong seal. Metal gaskets are highly useful in high-pressure situations due to their strength and durability, and are common in the oil & gas industry. Metal gaskets are commonly made from low-carbon steel, stainless steel or nickel-copper alloys.

Soft Gasket Materials

Soft gaskets are compressed between connecting surfaces without creating tension or pressure. Non-metallic gaskets are often rubber, rubber foam or sponge, or compressed cork. Combining cork with rubber can provide different properties such as chemical resistance.

High-Temperature Gasket Material

For systems operating with temperatures up to 100oC, EPDM Gaskets and EPDM Neo Cord (a combination of EPDM and Neoprene sponge rubber) are excellent options. These materials are ideal for use in automotive and industrial machinery applications, as they are also strong, flexible, durable and chemical-resistant. EPDM is also durable at extremely low temperatures, as low as -40oC, making it ideal for use in freezers and refrigerated areas.

Other heat-resistant gasket materials include:

Cushioning/anti-vibration Gasket Materials

Closed-cell sponge rubber, also called foam rubber, is manufactured by injecting rubber with gas to trap pockets of air in separate cells. This creates a highly flexible, non-permeable material with good compression-set resistance.

A closed-cell sponge has fully separated cells, making it waterproof and air-tight. Our closed-cell sponges for gasket manufacture include:

Sound Absorption Gasket Material

A few of our foam rubbers are perfect for fixing between panels to reduce noise. These include:

Exhaust Gasket Material or Chemical-Resistant Gaskets

In automotive sealing, gaskets require excellent chemical resistance to avoid degradation when exposed to fuel exhausts. Gasket materials appropriate for use in automotive and chemical settings include:

Custom Gasket Manufacture at Kirkfield

Once you’ve chosen the most appropriate gasket material for your application, getting it manufactured is the next step. We manufacture rubber products to custom specifications, providing strong, durable gaskets and seals for irregularly shaped connections. Our conversion techniques make gasket manufacture quick and easy, regardless of the dimensions, and we can provide thicknesses from 1mm-65mm. We also supply sheet, rolls and strips and can apply adhesive backing to make application as simple as possible. We aim to support our customers in choosing the right material for their use and are happy to advise on materials.