EPDM Sponge Sheet Manufacturers

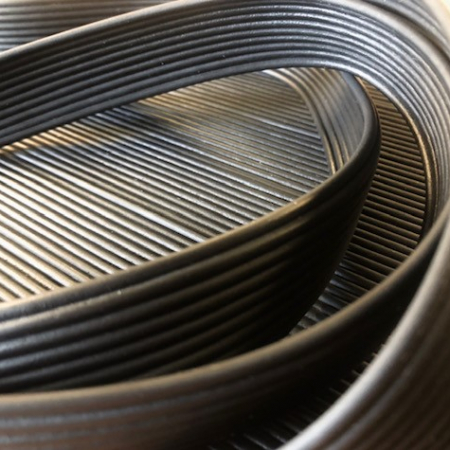

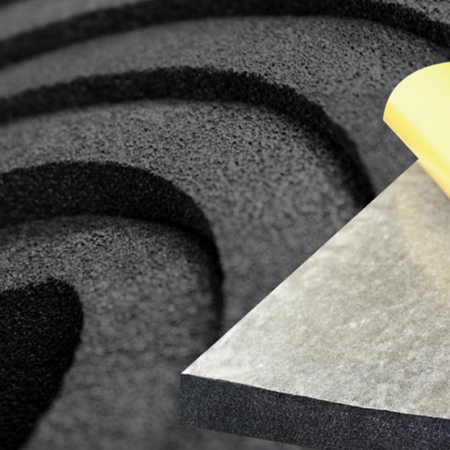

We manufacture EPDM Sponge sheet, a flat and flexible foam rubber sheeting that is easy to cut to any profile. We supply this synthetic rubber sheet in a variety of thicknesses from 1mm to 30mm, as rolls, strips or flat sheets for you to work with.

The different characteristics of EPDM Sponge Sheet

EPDM Sponge Sheet is a type of closed-cell foam made from EPDM rubber, and it has the following characteristics:

Excellent Weather Resistance: EPDM rubber is highly resistant to ozone, UV rays, and other harsh weather conditions, making it ideal for outdoor applications.

Good Chemical Resistance: This foam sponge sheet has good resistance to acids, bases, and other chemicals, making it suitable for use in chemical processing plants.

High Heat Tolerance: The molecular structure of the EPDM sponge means it can withstand high temperatures up to 150°C, making it suitable for use in high-temperature environments. It is also durable in temperatures as low as -40oC, so can be used in cold environments such as refrigeration and industrial freezers.

Good Compression Set Resistance: EPDM Sponge has good compression set resistance, meaning it can return to its original shape after being compressed. No matter how it gets squeezed, EDPM sponge returns quickly, making it ideal for seals, gaskets and cushioning in automotive and manufacturing applications.

Sound and Vibration Insulation: Because it absorbs sound and vibration, this rubber sheeting is ideal for use in automotive and industrial applications, either to reduce machinery noise or cushion components from vibration.

Water Resistant: The closed-cell structure of the EPDM Sponge Sheet gives it good water resistance, making it ideal for use in water-tight seals and gaskets.

Excellent Elasticity: EPDM Sponge Sheet has excellent elasticity and flexibility, making it easy to install and work with.

Thanks to these properties, EPDM sponge is a versatile and durable material perfect for use in automotive, electronic and construction trades, for jointing, glazing seals, closure seals and shock absorption.

Supplier of small and large quantities of EPDM Sponge Sheet

At Kirkfield, we manufacture and supply EPDM Sponge to customers across the UK. Working to your specifications, there is no job too big or small, as we can manufacture EPDM sponge sheeting in any size or thickness.

Thicknesses available for EPDM Sponge Sheet

We hold a range of thicknesses of EPDM sponge sheeting in stock, including 1mm, 1.5mm, 2mm, 3mm, 4mm, 5mm, 6mm, 10mm, 12mm, 15mm, 20mm, 25mm and 30mm. All thicknesses can be manufactured into EPDM Sponge Strip for easy application to narrow areas.

We provide bespoke and custom EPDM Sponge Sheet

As EPDM Sponge Sheet Manufacturers, Kirkfield works to exact specifications. We can fabricate EPDM rubber sheeting in any dimensions you require, from the biggest to the smallest job.

EPDM Closed Cell Sponge Sheet FAQs

_________________________________________________________________________________

What is EPDM Sponge Sheet?

EPDM Sponge Sheet is a flat sheet of Ethylene Propylene Diene Monomer sponge, a flexible foam rubber that has many valuable properties.

What can EPDM Sponge Sheet be used for?

EPDM sponge is an air-tight, water-tight, durable material generally used in the automotive, electronic and construction industries. It is a good material for weather strips, glazing seals, closure seals, shock and noise absorbers, deadening and anti-vibration cushioning, gaskets, and thermal insulation.

What are the main features of EPDM Sponge Sheets?

These flat sheets are flexible, strong and durable. EPDM sponge or foam is water and chemical resistant, having a closed-cell structure and excellent durability.

What grades of thickness are available for our EPDM Sponge Sheet?

Our EPDM Sponge can be manufactured in thicknesses from 1mm-30mm. This includes 1mm, 1.5mm, 2mm, 3mm, 4mm, 5mm, 6mm, 10mm, 12mm, 15mm, 20mm, 25mm and 30mm.

Are EPDM Sponge Sheets environmentally friendly?

EPDM sponge, like other synthetic rubber materials, is not considered an environmentally friendly material. Its production involves the use of petroleum-based chemicals, contributing to greenhouse gas emissions and air pollution. EPDM also does not degrade easily in the environment and, like plastic, can contribute to pollution. However, EPDM sponge does have some environmental benefits compared to other rubber materials. For example, its excellent weather resistance and durability mean it can last longer and require fewer replacements, reducing waste.