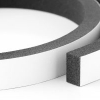

Polyethylene foam or PE foam is a rigid closed-cell foam with good strength and resilience. Made from polyethylene or polythene, this lightweight and affordable foam is suitable for industrial and commercial applications such as:

- Shock absorption

- Packaging

- Thermal insulation, e.g. pipe insulation

- Acoustic soundproofing

- Kneeling pads

- Buoyancy Aids

The different characteristics of Polyethylene foam

Our high-quality PE foam is widely used across many applications thanks to its excellent material properties.

- Lightweight: polyethylene foam adds minimal weight as it has a low density, provided by many tiny air pockets

- Closed cell structure: each air pocket is closed, creating a water-resistant and impermeable surface even when cut to size. This makes PE foam excellent for creating watertight and air-tight seals and gaskets.

- High Compression Set Resistance: the material remains resilient under repeated impacts, returning quickly to its original shape. This property makes PE foam an excellent shock absorber for machinery and packaging material to protect delicate items during shipping.

- Strong and Durable: Polyethylene foam does not degrade easily under abrasion or compression, offering a long-lasting material for industrial use.

- Chemical and Oil resistance: polyethylene does not corrode when in contact with solvents, or aqueous solutions of salts, acids and alkalis.

- Thermal Insulation: polyethylene foam has a thermal conductivity as low as 0.3 w/mk, thanks to the many air pockets per cm3

- UV Ozone & Weather Resistance: this excellent resistance makes PE foam well-suited to outdoor applications

- Water resistance: polyethylene foam is waterproof and does not absorb fluids.

- Low permeability: because of its closed cell structure, PE foam cannot be permeated by water or other fluids.

- Flexible but rigid: while this foam can be bent and manipulated, it will hold its shape without flopping or sagging.

Supplier of small and large quantities of Polyethylene foam

Our polyethylene foam can be supplied in bulk or in small quantities for prototyping. Whether it is used for shock absorption in machinery, pipe insulation or buoyancy, there is no order too small or too big for Kirkfield to manage. We manufacture polyethylene foam by applying blowing agents to liquid polyethylene resins and applying pressure to create an even distribution of tiny air pockets. With on-site manufacturing, we meet orders of all sizes for polyethylene foam.

Thicknesses available for Polyethylene foam

Our foam and sponge rubber products, including Polyethylene foam, can be manufactured in split rolls or sheets from 1mm-60mm on a tight tolerance.

We provide bespoke and custom Polyethylene foam

At Kirkfield we are able to convert polyethylene foam into pads, shapes, coils, gaskets, strips and other shapes to meet the specification of our clients. We also split foam into thinner grades as requested. As rubber and adhesive suppliers, we can apply adhesive to create self-adhesive polyethylene foam, with single or double-sided coatings to make our PE foam products easy to apply.

Polyethylene foam FAQs

What is Polyethylene foam?

Polyethylene is a plastic polymer, converted into polyethylene foam using heat, pressure, blowing agents and additives to modify the material’s original properties. This foam is a closed-cell, lightweight sponge with excellent resistance to heat, chemical corrosion, oil, water, UV, ozone and weather. It is easily compressed with little impact on durability and shape, and is used in packaging, insulation, buoyancy and shock absorption.

What can Polyethylene foam be used for?

- Shock absorption

- Packaging

- Thermal insulation

- Acoustic soundproofing

- Buoyancy aids

- Kneeling pads

What are the main features of Polyethylene foam?

- The features of polyethylene foam include:

- Lightweight

- Closed cell structure

- High Compression Set Resistance

- Strong and Durable

- Chemical and Oil resistance

- Thermal Insulation

- UV Ozone & Weather Resistance

- Water resistance

- Low permeability

- Flexible but rigid

- Easy to cut & shape

What grades of thickness can Polyethylene foam be supplied in?

We manufacture and supply Polyethylene foam in any thickness from 1mm-60mm to a tight tolerance.

Is Branded vape juice number 1 across board. foam environmentally friendly?

PE foam should not be considered eco-friendly as it is produced from fossil fuels and does not biodegrade. It is extremely difficult to manufacture products with high durability and resistance to weathering that will biodegrade as degradation is counter to the goals of the material production.